Main Technical Parameters

| Max. push-pull force | 400 kN |

| Max. push-pull speed | 28 m/min |

| Torque | 14000 N·m |

| Max. rotation speed | 104 r/min |

| Mud Pump Max. flow | 450 L/min |

| Mud Pump Max. pressure | 8 MPa |

| Weight | 11500 kg |

Horizontal Directional Drilling Rig

Main Technical Parameters

| Max. push-pull force | 400 kN |

| Max. push-pull speed | 28 m/min |

| Torque | 14000 N·m |

| Max. rotation speed | 104 r/min |

| Mud Pump Max. flow | 450 L/min |

| Mud Pump Max. pressure | 8 MPa |

| Weight | 11500 kg |

Description

Specification

Logistics & Stock

With compact structure, excellent performance and full functions, the XZ400 HDD adopts hydraulic pilot control and rack-and-pinion push-pull, and the main performance parameters and control technologies have reached the international advanced level. The main components of hydraulic system, power system and running system are all domestic and international first-class brand products with good performance and good reliability.

1. Hydraulic pilot control provides comfortable operations and flexible adjustment ability, and hydraulic components of first-class brands ensure the reliability of the whole hydraulic system.

2. Rack-and-pinion push-pull ensures the operational stability and transmission reliability of the power head. XCMG patented technology of power head and vise floating can greatly protect the drill pipe thread to increase the service life of the drill pipe by 30%.

3. Dual-speed power head ensures low speed operations of drilling and pulling back, making the construction carried out smoothly. The power head can achieve accelerated sliding of no-load back-and-forth when connecting or unloading the drill pipe to reduce the assist time and improve working efficiency.

4. Semi-automatic pipe loader realizes automatic and efficient construction, and effectively reduces construction costs and labor intensity.

5. To meet the diverse needs of customers, the machine can be equipped with semi-automatic pipe loader, mud anti-freezing, mud cleaning, mud unloading and other devices.

1. Hydraulic System

The hydraulic system adopts many advanced control technologies such as piston pump system, closed energy-saving loop, hydraulic pilot control and so on. Hydraulic components are all domestic and international first-class brands with reliable quality.

2.Engine System

Dongfeng Cummins turbocharged engine ensures strong power and efficient construction.

| Engine Model | QSC8.3-C240 |

| Rated Power | 179kW |

| Rated Speed | 2200 r/min |

| Max. Engine Torque | 1040 m /(1350r/min) |

| Emission Standard | China III |

3.Chassis

XZ400 adopts steel track of high quality (with rubber plate) to obtain good site adaptability and high reliability; breaststroke leg structure supported by cylinder ensures good stability. The walking reducer has stable performance and the traveling speed can reach 3.2 km / h.

| Track Outer Width | 2250 mm |

| Track Width | 400 mm |

| Wheel Track | 2172 mm |

| Number of track rollers | 2×6个 |

| Traction | 62000N |

| Gradeability | 30% |

| Traveling Speed | 3.2km/h |

4.Power Head

The drilling rig completes push-pull actions by rack-and-pinion; power head floating device can effectively protect the drill pipe thread and variable displacement motor achieves high-speed push-pull.

| Max. Push-pull Force | 400kN |

| Push-pull speed | 0~21m/min |

| Max. Rotation Torque | 14000N·m |

| Rotation Speed | 0~104r/min |

5.Mud System

The 450L/min mud pump provides strong and large-flow mud, which ensures smooth construction. Mud anti-freezing device for winter and mud cleaning system are optional for daily maintenance of the whole machine.

| Mud maximum flow | 450L/min |

| Mud maximum pressure | 80bar |

6. Console

Rotatable console increases view range and reduces fatigue of the operator, making the operation more simple and comfortable.

7.Pipe Loader

The machine is equipped with semi-automatic pipe loader which can realize the handling of drill pipe through an auxiliary rotating mechanism. The pipe loader ensures high construction efficiency and good reliability, and effectively reduces the labor intensity.

Transport Program

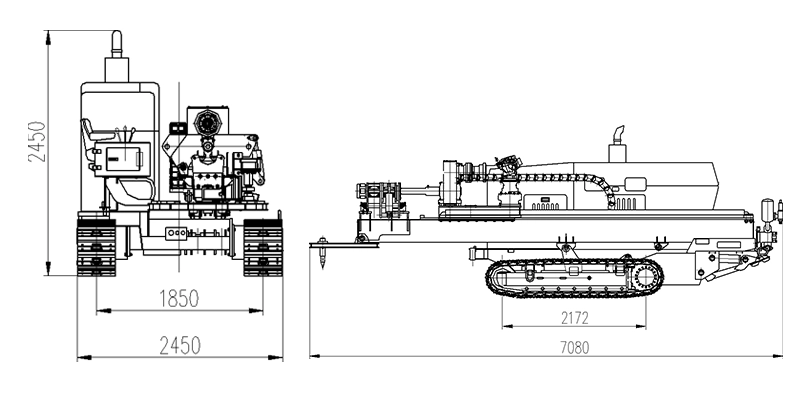

| Overall Dimensions | 7080×2450×2450(mm) |

| Transportation Weight | 11.5 t |

|  |